| CARVIEW |

Revolutionary War

The Continental Congress of 1776 sought to encourage enlistments and curtail desertions with the nation’s first pension law. It granted half pay for life in cases of loss of limb or other serious disability. But they had no money or authority so they left it to the states with lackluster success. Only about 3,000 Revolutionary War veterans ever drew any pension, and it was limited to those who had been disabled and the payments were quite low.

A new principle for veterans benefits, providing pensions on the basis of need (indigent), was introduced in the 1818 Service Pension Law. The law provided that every person who had served in the War for Independence and was in need of assistance would receive a fixed pension for life. The rate was $20 a month for officers and $8 a month for enlisted men.

The problem was that the pensioner had to prove that he was indigent and many never received a penny. In 1858 Congress authorized half-pay pensions to veterans’ widows and to their orphan children until they reached the age of 16, generally paying $4.00 to $10.00 a month depending on rank of the veteran.

Civil War

By 1868 New York Governor Reuben E. Fenton (“the soldier’s friend”) remarked that homeless veterans in New York State “numbered by the thousands.”

After the Civil War, veterans organized to seek increased benefits. The Grand Army of the Republic, consisting of Union veterans of the Civil War, was the largest veterans organization emerging from the war.

Until 1890, Civil War pensions were granted only to servicemen discharged because of illness or disability attributable to military service.

The Dependent Pension Act of 1890 substantially broadened the scope of eligibility, providing pensions to veterans incapable of manual labor. (Photo courtesy VA Dept.)

World War I

“The Veteran’s Bureau,” a columnist wrote in 1925, “has probably made wrecks of more men since the war than the war itself took in dead and maimed.”

After Dec. 24, 1919, all claims and payments arising from disability or death from World War I were regarded as compensation rather than pension. This was reversed in March 1933, when all payments to veterans were again regarded as pensions. It was not until World War II that the distinction between compensation and pension again was used.

The first director of the Veteran’s Bureau was relieved as director within two years and was later sentenced to prison and fined on charges of conspiracy to defraud the government on hospital contracts.

After returning from the Great War, many veterans faced destitution and did all they could to survive. In 1924 Congress passed the World War Adjustment Compensation Act, giving one dollar a day for service and 25 cents more for service overseas. There was a catch: If it was more than $50.00 it was issued in certificate form not payable for 20 years and not over $1500.00.

The veteran’s called these “bonus” certificates and marched on Washington, (see last 2 pictures above), some 15,000 by some estimates. They demanded immediate payments. They camped wherever they could. Some slept in abandoned buildings or erected tents. But many lived in makeshift shacks along the mudflats of the Anacostia River. With no sanitation facilities, living conditions quickly deteriorated in the “shanty town.

The bonus marches revealed serious shortcomings in how America cared for her defenders as they transitioned from military to civilian life. As a result, Congress passed the GI Bill of Rights. (Photo Courtesy VA Dept)

In 1933 Congress enacted the Economy Act which repealed all laws giving benefits for veterans and gave the authority to Roosevelt who radically created new acts that radically reduced veteran’s benefits.

World War II

In 1946, the VA had beds for about 82,000 patients but the VA rolls swelled to 15 million in just a few months and the hospitals were virtually all swamped. There were 26,000 non service related cases also on the waiting list. The VA was building new hospitals but had money for only 12,000 more beds. They came too few too late.

Health problems associated with atomic radiation also have received belated attention. The Radiation-Exposed Veterans Compensation Act of 1988 authorized disability compensation for veterans suffering from a number of diseases associated with radiation, 42 years after the exposure!

This specifically included veterans claiming exposure to atomic radiation during the detonation of nuclear test devices or during the U.S. occupation of Hiroshima and Nagasaki between September 11, 1945, and July 1, 1946

Korean War

Photo Lulu Vision Creative Commons License Find it Here

The Veterans’ Readjustment Assistance Act of 1952, called the Korean GI Bill, provided unemployment insurance, job placement, home loans and mustering-out benefits similar to those offered World War II veterans. The Korean GI Bill made several changes, however, in education benefits, reducing financial benefits generally and imposing new restrictions.

The effect of the changes was that the benefit no longer completely covered the cost of the veteran’s education.

Vietnam War

Photo eroksCom Creative Commons License Find it here

A major difference of Vietnam-era veterans from those of earlier wars was the larger percentage of disabled. Advances in airlift and medical treatment saved the lives of many who would have died in earlier wars. There were issues of Agent Orange which took many years to address. At first, the only allowable claims related to Agent Orange were for a skin rash, chloracne. The VA waited until 1991 to recognize for claim purposes two other ailments, soft-tissue sarcoma and non-Hodgkin’s lymphoma. (Photo Courtesy erokCom (Creative Commons License)

Vientnam veterans make up the preponderance of homeless veterans. 42% of the homeless veterans served in Vietnam. Many more served during the conflict but in non combat areas.

Many of these suffer from PTSD, alcohol and drug related illnesses that have not been properly addressed by the VA. The VA still claims that PTSD has no relationship to military service.

Gulf War

(Photo: Northwestfloridaonline.com)

Gulf War veterans are among the new faces of homeless veterans.

Afganistan and Iraq

News Headline: New York– Americans were dismayed to learn that soldiers wounded in Afghanistan and Iraq — “fallen heroes” were being warehoused in Building 18, a rat-and roach infested satellite of the Armu’s Walter Reed Medical Center.

- (Photo courtesy big gray mare A creative commons license

- Find it here

In addition, injured veterans are going bankrupt and losing their homes because the Veterans Administration (V.A.) holds up their benefit checks for years on end.

The men and women who fight for our country deserve better.

Is this any way to “support our troops?”

Update March 2010:

A Start

Source Politifact

VA secretary announces plans for more housing vouchers at Homeless Veterans Summit

Updated: Monday, January 4th, 2010 | By Robert Farley

On July 30, 2009, U.S. Sen. Jack Reed, D-R.I., introduced the “Zero Tolerance for Veterans Homelessness Act of 2009.” The bill would authorize a major increase in the number of vouchers available annually for homeless veterans through the VA Supported Housing Program. Specifically, the bill would increase the number of vouchers available to 30,000 in 2010, and then 10,000 more a year until 2014, when 60,000 vouchers would be available. The bill now sits in the Senate Veterans’ Affairs Committee.

On Nov. 3, VA Secretary Eric Shinseki convened the first-ever Homeless Veteran Summit in Washington, during which he unveiled an ambitious plan to establish new programs and enhance existing ones with the goal of ending homelessness among veterans over the next five years.

Oldtimer

Note: Some of the history information and early pictures came from the VA History website, later pictures came from recent posts and news articles, with attribution to sources. Link to Creative Commons License information.

]]>Insurance

Floodwaters are usually defined as water that touches the ground before it enters the house. That flooded basement where water came through the cement blocks will not be covered by homeowners insurance. You must have a separate flood insurance policy to be covered. Water that came through a hole in the roof or window that was caused by falling branches or wind generally are covered by homeowners insurance.

Apparently flood insurance is sold in at least three varieties. One that covers the house itself, one that covers only the contents (designed for renters) and one that covers the house and contents. Most mortgage companies only require the first. If you have flood insurance check to see if your furniture, carpets, clothing are covered or you may be in for a nasty surprise.

What are the problems involved?

Every home is affected differently by flooding. It depends on the type of construction and the height of the water in the house and whether it has been breached or moved by strong winds or moving water.

Breached homes (hit by floating debris or windstorm) and those pushed off of foundations have a high probability of requiring professional help or becoming not repairable.

All homes affected by flooding have one overriding problem: Water essentially ruins everything that it touches that is not waterproof. Drywall, carpets, furniture (particularly fabric covered), clothing, anything made of paper or cardboard, family documents, pressed wood such as found in inexpensive cabinets and flooring, and electronics all can be expected to be headed to the dump.

Most wiring, plumbing and some appliances survive, as does most of the framing if dried out soon and thoroughly enough. You should be aware that floodwater damaged homes can have lingering problems that may show up weeks, months, and even years later. If not properly dried out, you can have a “sick” house, one that is harboring mold, mildew and other toxins that affect those living there. Don’t take shortcuts.

Recovery Time Varies

You will notice that in areas where there is heavy flooding, some homes come back to life in a matter of weeks and others linger for a year or more and those often end up being removed entirely. If the home is salvageable, it is essential that work begin immediately and that a logical step by step process be followed. The suggestions here should help get a house recovered in the minimum time required to do it right.

Much of this article assumes the damage has been done and the waters have subsided. It is by no means all inclusive, but it is an efficient process to get your life back on track. It will take several weeks at best for even the lightest hit homes. Two months are about average for homes with water that rises above the baseboards.

Types of people affected. In my experience working on more than a dozen homes as a volunteer after hurricane Dennis in 2005, there are three categories of people affected. I’m going to address the rest of this article directly to them:

Renters. You should immediately contact your insurance company to seen if you have renter’s insurance that covers floods and then find a dry place to rent. You may also be eligible for assistance. Contact your local Red Cross, United Way, Salvation Army, or other prominent local service agency and see what is available. They should be able to direct you to a shelter until you get that dry place to rent. Some will be able to give rental assistance. Notify your church and your friends.

You should know that bedding, stuffed furniture and electronics (TV etc) that have gotten wet in floodwaters are almost never salvageable. Most lightly soiled clothing can be saved. Do not take anything wet into your new apartment. Take clothing to a commercial laundry and/or dry cleaners first. Dry the furniture you are trying to save carefully and remove all traces of mud. Put everything into storage until you find a new apartment. Consider volunteering to help your landlord or neighbors.

Landlords are those that have tenants in the house that was flooded. If you are a landlord, you should be aware that you will not get much priority in restoring your property except with paid contractors unless there are extenuating circumstances. You should first contact your insurance company and see if you are covered with flood insurance and follow their directions if you are. Let your church and your friends know. You should then contact local service providers, such as the Red Cross, for assistance with relocating your tenants but don’t expect to receive much more than referral of volunteers (who also want to help homeowners first). If you are old, infirm or disabled and this is your only source of income, then I expect volunteers to flock to help.

Homeowners are people who both own and live in the house that was flooded. Homeowners without flood insurance will have natural priority with service agencies and volunteers. If your flood insurance does not cover the contents, you may need assistance in replacing your personal property even if the insurance replaces your drywall for you. Everyone wants to get you back into your own home. You should first contact your insurance company and see if you are covered with flood insurance and to what extent (home only, home and contents) and follow their directions if you are. Let your church and friends know.

You should contact your local disaster relief agencies and service providers such as the Red Cross, United Way, Salvation Army, etc. in your area for assistance in locating volunteers to assist in recovering your house. The disaster relief agency may assist you in acquiring federal and/or state funding to help pay for some of the costs. If you do have flood insurance, then the volunteers should only be asked to help with the emergency part of the cleanup such as removal of furniture, etc. as the insurance will take care of the bulk of the work. If the contents are not covered, let the volunteer agency know and they may try to help secure donations to get you by.

As a homeowner without insurance, you will get the highest priority for assistance from volunteer agencies, depending on actual need. Some will assign case workers to work with you to help determine the need. If you have insurance, the need will naturally be less. If you are uninsured, elderly or with several children, you will go to the top of the list. If you are a retired banker, able-bodied and have good financial resources you will end up lower in the stack or left to hire your own contractor..

Damage Varies House to House.

What kind of damage can occur varies from house to house even in the same neighborhood. Some may be on concrete slabs and others sitting on cement blocks. Some may have basements and others not. Some may be further up the hill and get small amounts in the crawl space or onto the walking surface, while others may be up to the rooftops. Some may have pressed wood siding, others brick. Everything causes variations in the damage done and the cost of restoring the house.

Utilities and Government Actions

Condemned Sign Posted. You can expect your city or county code and health departments to pay a visit and may put a condemned sign and yellow tape on the door to your property. That does not mean your house has to be torn down or can’t be fixed. It means you can’t live in it until they agree it is safe to do so. You should make an appointment with them and be ready to outline your restoration process. They will usually let you go inside and begin cleanup operations.

You should be aware that there is a process whereby a house or neighborhood can be condemned and removed. It does happen when the damage is so severe that it cannot be repaired or the risk of being flooded again is too high, often after repeated floods. It is a long process and involves the government purchase of the land at fair market value.

Utilities Turned Off. You will also find that the various utilities will likely turn off the power at the pole and gas and water at the street or the meter. They may even remove the gas or electric meter. This is for your safety. You won’t need them to begin cleaning the place up. If you have equipment you need to use (a commercial dehumidifier, for example) you can ask for an inspection of your wiring and they may restore it.

Otherwise you can ask your utility for a “construction” or “temporary” meter and they will put one in your front yard that you can use to run power equipment. Interior wiring, including light switches and outlets are not usually harmed by flooding waters. This is because the circuit breakers often save them (and you). Your local inspectors will look at them before they let you restore poser.

The Recovery Process

Concrete Slab Construction Houses built on concrete slabs usually fare the best in the long run. However they may also have the deepest water in their homes. The furnaces and ductwork are usually above the floor and are more easily cleaned or replaced and since there is no crawl space, the flooring will not likely be damaged other than carpet and loose tiles or any wood flooring on the slab.

Crawl Space and Basement Construction: Houses built with craw spaces have a whole range of additional troubles. Standing floodwater in the crawlspace or basement will quickly cook up a brew of mold and mildew that will take a commercial service to kill it, if it can be done at all. You need to work fast to avoid serious problems.

Often the furnace is under the house or at least the ductwork and usually both will be full of water even if the water did not reach the walking surface. In addition, the sub floor (layer under your exposed floor) is often pressed-wood that has aged and will soak up water and begin to rapidly deteriorate. It is a difficult and dangerous environment to work in and it should be professionally dried out before entering.

All Houses:

Must-Do-Immediately Tasks

This list includes everything down to cabinet removal and sometimes power restoration, but it is critical to do it quickly. A lot of this is do-it-yourself level work but get all the help you can get It will take 4 to 10 people to just clean out the house. 20 would be a blessing and can be done in a few hours.

Everyone should be equipped with gloves, mask, long sleeves, long pants and shoes with non slip soles and cover the entire foot. There should be hand sanitizer available and lots of paper towels. This can be a dangerous job from the standpoint that there may be hidden broken glass, exposed nails as the drywall is removed, and critters looking for refuge as well as toxins already brewing.

Explain safety rules and the process. Start the day by outlining the safety considerations, then explain the process so that overzealous helpers do not get carried away and get ahead of the curve. Ripping off the drywall before you take off the door and window trim and the switch covers can add to the expense of recovery. Piling things in front of the doors or walkways and interior traffic patterns will just slow things down for everyone. Request that any nails in boards be bent over and turned down when thrown on the pile. Boards to be saved that have nails sticking out should be placed separately out of all walk patterns, preferably standing in a garage corner or tucked against an exterior wall.

The following instructions include all types of construction. The object is to get everything wet out of the house ASAP. This includes furniture, interior doors, carpets, baseboards and drywall to the extent it got wet. Be aware that you may have problems not considered here. Open all the windows and doors when you have workers on the site. Keep the windows partially open until the house is dry.

Get the furniture and other belongings out of the house, or at least off the floor that was flooded. Tag salvageable items and/or stand at the door to direct those things you want to try to save to a separate area well out-of-the-way, preferably dry like a carport. You will want to put anything salvageable into dry storage, but clean and dry them first. If the water made the carpet wet or if you can detect a moldy smell, it is not likely to be salvageable. If there is the least doubt, you should get a professional cleaner to look at them first

Wet carpets from floodwater have tiny microbes and spores galore that will fester over time and promote sickness later, even when well dried. Wet carpet will slow down your progress by a week or more if you keep it in the house. Pull it up as soon as possible and also remove the padding and take it all out to the curb. Most communities will do free pickup of flood damaged debris.

In almost all cases the baseboard and wet drywall will need to be removed to prevent mold from growing inside the wall..

Remove the baseboards first. If done carefully, some baseboards can be saved in a dry place. However, old wet wood will often split. Removal should be done with a flat iron pry bar, not a hammer. Sometimes you can punch a hole in the drywall and simply pry the baseboard off with the pry bar. Number the baseboards if you plan to try to save them so that you can put them back in the same place

Remove the electrical trim plates. Put them away in your car or a drawer somewhere with the screws or plan to buy new ones. They have to be removed to replace the drywall later, so put them away now.

Remove the interior trim on all doors and windows – number and save the trim. Removing the trim will aid in removing the drywall and will also open up spaces for captured moisture in the hidden spaces in the casing to escape. You may get the wet drywall out easily with the trim still on, but you won’t be able to get the new drywall in with the trim still in place, so remove it now..

Remove the interior doors and casings. Number them and remove to a dry place (garage or corner of a carport, for example) to aid in drying them out and to protect them. Use a saws-all to cut the nails through the casing shims if you have power, else pry carefully in stages all around using the flat iron. Doors with laminated wood facing (Luan) should be thrown out as they will just come apart later. Hollow core panel doors will sometimes separate but sometimes can be glued back after they are thoroughly dry.

Remove the wet drywall. Find the highest wet drywall level and go at least 4 inches above that. Try to select a point 1, 2, or 4 feet from the floor to make your new drywall go further. draw a chalk line at that level, cut and remove the drywall from there down. This is best done with a drywall hand saw. Make the cuts at a shallow angle as there may be wires or even pipes or air conditioner lines in the wall. I don’t recommend a ”saws-all” except in the hands of someone very capable and careful. I’ve seen a lot of cut wiring and pipes that greatly increase the cost of repairs. It is an easy job with a good drywall hand saw. If the cut does not follow the line carefully, it will slow up replacement later.

If the water level was above 4 feet, remove all the drywall. If the level is below 18 inches, take out the bottom 2 feet. If below 8 inches take out the bottom foot. Go higher if the drywall feels damp less than 4 inches from the lines mentioned here. Doing this in 1, 2 or 4 foot increments will reduce the amount of drywall you have to buy and reinstall because the sheets are easily cut to narrower widths and will go further. Take out all the drywall in a line all around the house. Don’t forget the closets as they will be the worst to mildew.

Punch a hole in one of the wall cavities with a hammer or prybar below your cut line. Grab the sheetrock with your hand and pull it off and have it carried outside onto a portion of the driveway. Often sheetrock will come off in large sheets.

Remove the nails. Have someone come behind as each wall is cleared and pull the drywall nails and remove any screws. Put them into a bag or can for disposal later. Nails that break off can often just be driven in flat. Have someone check the studs by running the edge of their hammer up and down them and along the bottom plate to detect any missed ones. Nails left on the wall will be snags for anyone working close by and will cause damage to new sheetrock if not noticed in time. May as well be systematic and find them all now.

Remove all bottom cabinets. Remove the bottom cabinets in the kitchen and bath, but start with the counter tops. Counter tops will usually have screws underneath that you can find (use a flashlight) from the open areas underneath, often in corners and near the middle. These hold the top to the cabinet. Sometimes there is also putty. Remove these screws, cut along the caulk along the back edges of the splash board.

Verify that the water is turned off at the meter, disconnect the faucet lines and, if necessary, remove the cutoff valves under the sink. Take out the trap and tape a plastic bag over the drain line. Remove the countertop by using a 3-in-one tool or flat iron prybar to lift the front and pull it away from the wall. Decide if you want it saved or not.

Remove the bottom cabinets. If you desire to salvage them, look behind the drawers and inside the back and remove any screws you can find that are holding them to the wall. Usually there will also be screws hidden behind the door edges in the front frame that hold the cabinets to each other unless they are built as one unit.

Remove all the screws and then use a sharp drywall knife to cut through any caulk between the cabinet and the wall. Slowly pry the back of the cabinet from the wall with a flat iron all around in stages so as to detect any missed screws. Older cabinets are often below the floor level as new layers of vinyl have been added over the years. They are seldom nailed to the floors, Tilt them forward and lift them up with a prybar.

Usually you will end up finding that the cabinets cannot be saved, but it is worth a try. Be aware that most modern cabinets have significant amounts of pressed wood and will harbor mold even if they don’t deteriorate during the flood. The cabinets must be removed to get to the drywall behind them and to the open spaces below them anyway. If the cabinets look good and the pressed wood has not deteriorated, Kiltz the back and bottoms of the cabinets (inside too if possible) to reduce the chance of mold and mildew later.

In my experience any cabinet that is no longer sold as a “standard” cabinet will also require you to remove and replace the top cabinets as well. Might as well do it, although I’ve managed to save two sets of top cabinets out of maybe 10 or 12 houses I’ve worked on.

Inspect the sub floor from the basement or crawlspace if you can get in there. At least look at the area over the crawl space door. If the sub floor is coming apart you will have to remove all of your flooring to get to it, remove and replace it all. I was in one house as we were removing carpet and someone broke through the floor. No injuries but the floor under the carpet was simply pressed wood (OSB) and was falling apart (it had termite damage too).

Houses with crawl spaces will usually require professional help. At the least, any trapped water needs to be drained from under there. This can be done by carrying in dry dirt to fill pockets of standing water, and by using sump pumps for sunken areas of the crawl space and basements.

Often the fuse panels and laundry are in basement areas. Furnaces are often in basements and many times in crawl spaces. Duct work can still be filled with toxic water and must be cleaned or removed. If it is flexible duct work, punch holes in the bottom of low spots, let the water drain, then remove them and replace with new duct work after the house has been dried out. A commercial dehumidifier and/or large blowers will be required to dry the basement or craw spaces completely. Any moisture remaining will just promote mold and fungi growth.

Mold and mildew will begin to grow on wet wood in the crawl spaces very quickly! You will see white spots and some with “hairs”. Black mold is the most dangerous and should be avoided completely. It will take commercial products made for the purpose to kill them. A thinned bleach spray will also work, but the danger to non-professionals doing this job is very high and loss of vision, lung and skin problems can be very serious. Vapors from cleansers will seep into the living areas and can be dangerous to anyone working above. Let everything dry and air out completely after using them. Professionals have the tools and the safety clothing and hoods to do this with no danger.

Get power restored. With any luck you can do that while you are still doing demolition if an electrician and the inspector agree. If not, there will be a point where you have finished the demolition where you can have an electrician and/or government inspector verify the safety of your house for electrical purposes.

That inspection may allow you to restore power. If the power system of your house is heavily damaged, consider asking the power company to install a temporary meter and pole in your yard. The point is that you need power to run fans and dehumidifiers to aid in the drying out process.

Drying it out. (1 to 3 weeks) Many governments require you to be inspected to verify that the house is dry enough to begin reconstruction. This means you can’t begin installing the new drywall until they say you can. If you get ahead of your inspection curve, you may be required to remove the drywall, inspect and replace it again. Work with your inspectors. They are your friends looking out for your safety.

Be aware that some cities and counties require the drying out process to be at least two weeks before they will inspect it. Ask them. If the wood is obviously dry you may get them to make an exception based on hardship. For your own good, it must be completely dry. Be nice to them at all times, very, very nice. particularly if you need some sort of exception, because they can make it easy or hard. They are nice people anyway, just doing their jobs but they don’t have time to argue with you. I am not and never have been an inspector if you are wondering. I’m just going from experience. Ask them what they expect you to do. It is ok to negotiate some and tell them why it is important to you , but don’t argue. Kiss of death. Besides there are good reasons for allowing wood to dry for a minimum amount of time.

Keep the screened windows open during dry weather and open the doors as much as you can. I’m not recommending that the doors be left open when no one is there. Close the windows partway up and lock them into place with a nail if necessary. Move the equipment around until the wood is obviously very dry, not “kinda” or almost dry.

Rebuilding – Get an inspection. Your inspector will want to check the dryness of your home, and will also want to look at the wiring and pipes that will be hidden later. If you had to have your flooring removed, then you will need them to look at the framing there too. Install the flooring if necessary and have it inspected. These inspections are for your own good. Always insist a contractor get a permit. While your inspector is there, ask him or her if they want to see the drywall nail pattern before you paint. Some do.

Drywall first. Once your inspectors give the ok, start putting up the drywall. Recheck the studs and bottom plates for overlooked nails first. Lay it sideways and make sure the thickness is the same. We had one house with a mixture of ½ inch and 5/8 inch drywall and some volunteers put in all ½ inch. I had to come behind them and replace a lot of it. 5/8 is typically used as firewall material, sometimes found in and outside furnace closets and walls that divide two apartments. and in flue chases.

Be aware that you can now buy “paperless” drywall. This is moisture resistant and does not provide anything for mold to grow on. It uses a fiberglass backing instead of paper. It costs more but if you have a damp basement that you choose to not waterproof, then use the paperless drywall material. Use “green rock” water resistant drywall in bathrooms.

Lift the drywall off the floor by the thickness of a scrap piece of drywall so the bottom never touches the floor. This reduces the chance that mopping or minor leaks or knocked over mop buckets will damage your new drywall later. The gap will be covered by the baseboard. Try to fit the drywall close to your cut line. Use a sharp edge or sanding block/rasp to remove rough edges and humps to get a tight fit.

Tape, mud and sand your joints. It usually takes 3 coats done over 3 days. A good drywall man can do this at little cost and you will never see the joint. Be aware that most off-the- street “expert drywall installers” may never have worked on drywall before, they just need a job or saw it being done somewhere. They will not do the job you need. Almost anyone can paint, but drywall mudding requires some experience. Get references and only use someone who does it for a living, a professional. A poorly done job will haunt you forever. Every line will show.

When the drywall is finished – all 3 coats and sanding – run your hands over all the joints. If you can feel the joint, it will show when painted. Fix it.

Prepare the door casings for reinstallation. I don’t recommend knocking the nails back through the wood. Use vice-grips to pull them out the other side (the side that never shows) or use a metal-cutting blade to cut them off flush with the wood (easiest). Pull any that have heads showing on the edge of a board where the trim was peeled off, or drive them in flush. Throw away the old nails and use new ones. Knocking them back out always damages the wood. The heads are embedded and split out ugly chunks of wood.

Install the doors. Then begin reinstalling the door casing and window and exterior door trim. Make use of the numbers you put on them when they were removed. Most will fit back easily where they came from. How the door closes and whether or not they stand still when opened is dependent on the door and its casings all being perfectly vertical. Make absolutely certain that the door casings are vertical. Use shims to get both sides vertical and spaced so that there is about 1/8 inch gap on each edge of the door, sides and top. Do the base boards last or you will have trouble installing the door trim.

Install the kitchen and bathroom cabinets. Do not install the baseboards on cabinet walls until you have the cabinets installed exactly as you want them. Put the tops on last. Make certain that plumbing hasn’t been damaged or clogged with debris before hooking the faucets and drains up. You may want to replace the valves under the sinks with new ones.

Caulkaround all the new trim and new cabinets next to the drywall. Use paintable caulk for everything. Some caulk just will not take paint and will look bad when you are done. Read the labels to be certain it is paintable. Latex is good. Sometimes large boxes of donated caulk show up. Be aware it sometimes is donated because it has started to harden or is a non paintable stock that is moving slow. They are a write-off for the company but not useful to you. Don’t use it if it is hardening or wrong type.

Inspection? Some inspectors want to look at the nail pattern in your drywall before you paint. This applies mostly to new houses but you should check with them first.

Sand, fill nail holes, and Paint everything, Painting is to beautify and protect your work. Too often the paint is slapped on walls and wood work that are not ready and the beauty part is lost. Visually inspect every piece of wood for nail pops and sink the heads with a nail punch. Fill the heads with wood putty. Sand any areas that have paint chips and thin coat (even drywall mud will work) anything you can feel is rough with your bare hands, let dry and then sand again. Prime the filled areas and all new drywall.

Install carpets. Let your carpet supplier do this for you. Most people do not have the skills required. After all this work, why have carpet with twisted with obvious wrinkles and loose areas showing? People will think you just reused your old carpet. Get it done right.

Get a final inspection and move back in.

Whew! Get that flood insurance now!

It will cost you only a few hundred bucks a year. Our area has had two 100 (plus) year floods in 4 years. Three in 45 years. It will happen again.

Note: there are at least 3 types of flood insurance. One for the house, a rider or separate insurance for the contents, and one for contents only. Most mortgage companies and any federally assisted mortgage requires flood insurance on the house (only) if if it is in the FEMA designated 100 year flood zone. This insurance can be purchased by anyone outside the flood zone, usually at a greatly reduced price. Be aware that it does not protect the contents unless you purchase that additional flood insurance.

It is my understanding that there is a 30 day waiting period for flood insurance to go into effect. You can’t hear a hurricane is coming and then decide to get flood insurance protection at the last minute.

Your homeowner’s policy does not cover flood damage to your home or its contents. You may see words that seem to cover it, but those apply to water coming through the roof or from broken pipes inside the house, not anything that comes through a patio door, seeps under a wall or pours out of a crack in a wall from the outside because by definition, those waters touched the ground first and thus are flood waters not covered.

You may live high up on a hillside with one side of your finished basement or downstairs area embedded against fill dirt. The nearest flood zone maybe 400 feet below you. However, if you develop a leak in your block wall and your carpet and drywall, clothing, furniture, electronics, etc. get wet, your homeowner’s policy will not cover it. Water that touches the ground first is considered flood waters even if it was not an overflow from a stream. So get flood insurance for at least the contents of your home. If your downstairs area has drywall, consider getting flood insurance for your home as well. It is cheaper if you are not in a designated flood zone.

If you own and live in a flood zone or rent to someone and furnish the carpet, etc, get flood insurance for both the house and contents in addition to homeowner’s insurance.

Renters can get flood insurance on their personal property. If you rent and your apartment gets flooded, you need to have that flood insurance on your property. The landlord is not liable in almost all cases.

I hope you were reading this just-in-case. If you are affected by a flooded house, my prayers go with you. Take care. Remember things are different case by case. I do hope that this helped you in some small way.

Oldtimer

]]>Note: If you came here looking for the homeless veterans site, this is it! If you came here looking for the homeless youth site, this is it!. I’m just taking a break to help out on a Habitat House and once a year I post what I saw, experienced and learned. Click on either of the two links in this paragraph or go to the side bar and select a category or search for what you want. Also look above the banner or to the right for popular articles on Homeless Veterans.

Tutorial – installing roofing shingles

Roof Ready For Shingles

This is the way Habitat volunteers see the house when they arrive on the scene on roofing day. Soon the roof will be covered front and back with volunteers. It is essential that the roofing be done early in the day and that there is plenty of water available. The felt and starter shingles are already in place.

We need to start this tutorial a little earlier than that.

Drip Edge Installation

This drawing illustrates drip edge installation. The drip edge must be installed in the order shown. The drip edge is a metal extrusion that goes along the horizontal edge (eave) of the roof under the roofing felt and along the sloping edge (rake) of the roof above the felt. Install the drip edge for the eave before the roofing felt is installed. Install the drip edge for the rake after the roofing felt is installed. Attach the edge using 7/8 ” roofing nails on 24″ centers. Unlike shown in the drawing, the rake edge goes all the way down and overlaps the eave edge. Trim the rake edge to match the eave using tin snips. When two pieces of drip edge meet in a joint, overlap the joint by 1 to 2 inches by trimming the top of one as needed to allow them to overlap. Joints on the rake drip edge should should have the upper one overlapping the lower one.

Also shown in this illustration is something called the “bird box”.

Click here for the rest of this tutorial:

Bird Box

This is the “bird box” detail for the corners of the roof. It is simply a 2 piece box that adds detail to the house and provides a place to mount corner lights. It just adds to the overall looks. Notice the rake drip edge is shown trimmed in this illustration and runs all the way to the facia.

tweet tweet

Roofing Felt Installation

Roofing Felt Installation

Starter Shingles

The edge of the roof is outlined with starter shingles that are placed on the roof with the tabs turned inward. This provides extra strength near the edge, higher wind resistance, and better resistance to water blowing under the edge of the shingles. Before starting, snap a line 11″ from the drip edge on the eave all the way across the roof. Have someone hold the line down in the middle of the roof and snap each side separately to minimize bounce and sag. Repeat for the rake (sloping) edge.

The starter shingles are nailed along this line, allowing a uniform 1 inch overhang of the shingle over the drip edge on both the eave and rake (12″ shingle on 11″ line). Notice that the eave edge starts with a shingle that has 1/2 tab cut off (6 inches) in the drawing, although that is optional in many areas. Outline the roof completely with these shingles. Butt the starter shingles end to end (do not overlap). Each shingle gets 4 nails located near and opposite the beginning of the drip line. See drawing “shingle layout below” if there is any doubt.

Starter Shingle Photo

Shingle Layout

Shingle Layout

Shingle pattern for multiple crews

Trimming the Edges

Shingles Overhang Rake Edge

The shingles should overhang the end (rake) of the roof and droop down until the entire roof is covered.

Pipe Flashing

Pipe Boot

Shown above is the proper installaion around a typical vent pipe. The flashing will already be there but not nailed down. Lift the flashing up and run the course below up to the pipe and notch as necessary. In the case shown above the pipe flashing has been dropped over the lower course and the follwing courses lap over the upper parts of the flange so that water sheds properly. The boot is sealed to the roof with asphalt calking and nails below shingles. Any nails are calked and located under shingles.

Shingles for Valleys

Valley Weave

There are two ways to install shingles in valleys. Both start with a 14″ wide aluminum sheet pressed into the valley from top to bottom. Roll out the aluminum and form it to the shape of the valley down the center of the sheet. Nail this sheet only on the long side edges. No nails within 6″ of the center!

Valley Weave

The drawing above shows the valley weave technique that is usually used on valleys between two roofs on the front of a house, sometimes also on the back. Shingles woven together both look better and hold up better to water dammed up from leaves on the roof.

Shingles from the shorter roof are extended to and lap over the valley but the ends on the other side are not nailed down at that time. Shingles from the other roof are woven in by crossing over one shingle and slipped under a shingle in the next course and nailed down. Form both sets of shingles snugly to the bottom of the valley. It is best to trim the ends as necessary to not extend under more than one course at a time to avoid a lumpy appearance. Do not put any nails within 6 inches of the valley from any direction!

Valley Weave Photo

Standard Valley

Install the aluminum as described above. Run the shingles from the shorter roof side over the valley and lap the other side by at least 12″. Make certain that no end joints end up in or near the center of the valley, preferably end them near or past the edge of the aluminum. Form the shingles snugly to the bottom of the valley. Do not place nails within 6″ of the center of the valley at any time from any direction!

Snap a chalk line down the center of the valley. Now extend the other side of the roof past the chalk line and cut it to match the chalk line. Cut only the newer layer, not those from the short side. The effect is one side is slightly higher than the other, forming a small step. Apply a bead of asphalt caulk about 1″ back from the cut edges and press it in.

Standard Valley Photo

Ridge Caps

Ridge Cap Photo

Making Ridge Caps

Ridge Vent Installed Photo

Ridge Vent, Top View

Bottom View Photo

Slide Show of Tutorial Pictures.

This Roofing Tutorial slide show contains all the pictures shown here and quite a few more.

Here is a link to the Roofing Tutorial pictures

Here is a link to my Habitat Build Photo Sets

There is at least one more tutorial coming, Hardi Plank siding.

Do you find these tutorials and pictures useful? Please let me know!

For those of you looking for the homeless veterans or homeless youth, this is also it. Click on one the links above the banner or on either of the two links in this paragraph, or maybe check out the right sidebar.

This article covers the installation of the roof shingles, Hardi Plank siding, and various other 3d day activities. From any slide show you can access various sizes of the prints for free download (instructions further down – “Getting Copies”).

Link to slide show – 170 pictures Click on picture or here

Link to a collection of all Habitat pictures (2007 and 2008) organized one set per day!

Getting Copies

The pictures shown here and in the slide show do not have the resolution you can get if you download them from the Flickr site. If you are viewing a slide show containing the picture you want, click on the link at the top left of the slide show to get to the full set at high resolution, or click on any picture in the slide show and then click on “View Main Page”. If you are looking at the mosaic of of a set for a particular day, you can click on the picture you want. Once there, you can click on the button above the picture “All Sizes”. It will open in the large size, but you can download any picture in any size free, or can order prints through the site that will be delivered in about an hour to your nearest Target store. It’s not obvious how to get to the Target option. First put a print in your shopping cart. When ready for checkout, you can send your prints to Target for printing for about 15 cents per copy or have them mailed to your home.

In addition, you can go to “Zassle” and have T-shirts, coffee mugs etc. made with your favorite print. Enjoy. Below are selected prints but only a small sample of what is available for free download.

The Third Day

It’s amazing what has been accomplished in the first two days! Not only are the walls up, but the walls are all up, the roof is decked and dried in, the exterior walls are covered with OSB, the windows are in all in and all but one door has been installed. Today the plan is to put the shingles on and get a good start on the siding.

The day, as always, starts with an orientation for new volunteers, a pep talk, then a safety talk and an introduction of the homeowner by our SPM (Site Project Manager), Jeff Vanderlip. If you peek through the tent above the person in the white tee-shirt, that is Jeff in the orange tee-shirt and floppy hat facing us. You can see that a couple of workers are already on the roof even before the rest of us get started. They are laying “starter” courses for us to work from. More about starter courses later.

Nicole Combs is the future homeowner and also in the picture. To the left of the tent is a man with a purple cap. Nicole is on the far side of the picture just to the right of him. She is also in the top picture right in front of the wheelbarrow (yellow shirt).

And this is Elijah. He is the son of of our future homeowner. He has a keen interest in what is going on as he will be living here, but he is too young to work on the site. When around, he is confined to the food tent or visiting inside after the work is done and helping clean up the property or just playing nearby. A great kid.

Shingles!

This is essentually the way we found the roof this morning. The starter edge courses are alrady in place and the bundles of shingles are on the peak of the roof. The shingles you see along the edges were put there by the Gray Ghosts that I’ve mentioned a number of times in my earlier posts.

The two people on the roof are putting on starter courses that run up the centerline of the roof in such a way that volunteers can work off each side of the centerline toward each edge of the house. That way at least four crews of workers can work at any one time. They’ve also started the porch roof and valley so that the valley shingles can be put in as a “weave” for good looks on the front.

To see the rest of this article and some great pictures, click here:

A look at progress after just a few minutes of volunteer work. The starter course is the patch of roof that runs all the way up. Volunteers can use that as a pattern on each side to work toward the edges. The ladder is on a stand-off to protect the new edge.

View of back of the house. Busy busy busy! Moving along nicely. People on the ground are getting ready for siding.

While the roof work is going on, others are on ladders finishing putting up the Tyvick roof wrapping.

This is the way the house looked by noon. After we broke for lunch the roof was too hot to send volunteers up to work on it. The tar in the roof had began to melt and if not walked on very carefully, could come loose and slip out of position, not to mention that volunteers could get burns and/or be overheated. Two experienced people went back up to finish and remove equipment. Notice the roof vents are installed at the top.

The tutorial which I am preparing has many detailed pictures of the valley, roof peaks and other construction features. Come back for that if you have an interest. The roof will be trimmed later in the week by the Gray Ghosts. I’ve done that job before and it is hot and tedious but fairly easy to do. Snap a line and cut along it very carefully.

Siding!

Gary gives us a demonstration of how to properly prepare a joint for the Hardi Plank siding. This is a change in procedure from years past. Notice a small piece of Tyvek has been inserted behind the plank. It has been stapled to the wall, then the edge of the plank and Tyvek is caulked. The next plank will butt up to the caulk and squeeze some of it out. A wet rag will wipe off the excess after it is nailed up and we are done. Joints always have to align with an interior stud. They cannot be within two studs of each other or be one over the other without at least 3 boards in between. They can’t occur directly under or over a window nor over a door frame. They have to be staggered and each joint receives the treatment as shown above. When joints occur above the bottom course, the Tyvek laps over the lower course slightly. So much to think about… nothing gets slapped up. It has to be done right – this is a Habitat house.

These young ladies are staying ahead of the siding crews. They are marking the studs. Someone always makes a joke about that. The studs have been marked on the concrete foundation below the walls and they use a level to extend that mark up so the siding crew will know where to nail and were to place the ends.

That is our Gray Ghost leader in the red hat. Checking our work. Most people do not know the wonderful job they do and how much work they have saved the volunteers.

Here a crew leader (hidden behind the worker) is giving close instruction to a volunteer on the proper way to nail the planks while another watched in the background.

Here the edges of the planking receive a final coat of caulk next to the store room door. All edges get this treatment. It is important that all edges and all exposed nails (such as along the top course) are caulked and all siding receive two coats of exterior paint.

Hmmm. I think we have seen this view several times before.

These two gentlemen are perhaps two of the most experienced Habitat volunteers in the country. Certainly in Cobb County and the metro Atlanta area. They are both SPM’s, both Gray Ghosts and have led and built houses all over this area. It is a pleasure to know them.

On the left is Roy Brumley and on the right is Jim Miller. You can find the website of the Gray Ghosts here. Don’t tell anyone that Jim Miller was on site. If you go to the Gray Ghost site you will find that I’m listed, but I’m not really qualified nor active enough to be listed. On the other hand Jim Miller is not listed. The reason for that is he is working on Habitat houses in another county and is an unofficial guest SPM at our site. He was the lead SPM for our Presbyterian Coalition for so many years before he left to work on Habitat Houses elsewhere that we invite him back every chance he is available. We love him and Roy so much. Don’t tell them I said that. Roy is the lead Gray Ghost and schedules their work.

Don’t forget to look at the slide show and/or picture sets (see link below the top picture of this blog article) and please come back for the tutorial when it is finished. If you click on the orange square below my picture below the banner of this blog, you can sign up to be notified each time I update this blog. Don’t worry, you can opt out at any time. No charge for either.

Enjoy,

Oldtimer

]]>

Note: If you came here looking for the homeless veterans site, this is it! If you came here looking for the homeless youth site, this is it!. I’m just taking a break to help out on a Habitat House and once a year I post what I saw, experienced and learned. Click on either of the two links in this paragraph or go to the side bar and select a category or search for what you want. Also look above the banner or to the right for popular articles on Homeless Veterans.

This is a a drawing I made of a generic roof truss, not too unlike what is actually installed. At least most of the parts are here. Below are pictures of the trusses we actually installed and you may note some minor differences. The major difference is the end trusses which have more vertical 2×4’s in the web so that there are places to nail OSB and siding. None of the ones we put up have a King Post.

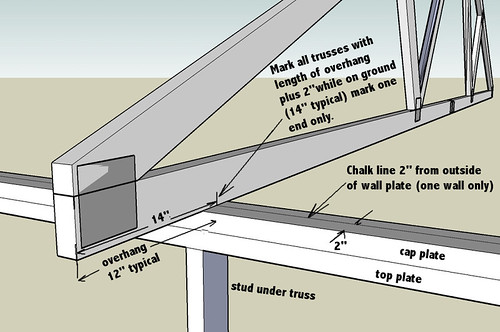

The trusses are marked with alignment marks while still on the ground. Each truss is marked 14″ from one end (only), that end being the end that goes on the longest wall, (in our case the back wall). A line is snapped along the back wall exactly 2″ from the back edge of the cap plate. The corresponding 14 inch mark on the roof truss allows for a 12 inch overhang and the 2 inch offset in the snapped line. When the roof truss is slid into place a volunteer aligns the truss mark with the snapped line on the cap plate. If one end is right, then both ends will be right on these manufactured trusses.

I was one of the two marking the trusses. The other was Max, son of our SPM, Jeff Vanderlip. Each truss also receives a mark along the top plate/top rail at 47 1/4 inches and at 9 feet. These marks go on both ends of each truss. The 47 1/4 inch mark is the top edge of the beginning course of the OSB deck (which allows for a 3/4 inch overhang over the end of the truss. 3/4 inch fascia board stretched across the ends of the trusses will take up this overhang. The 9 foot mark is the location of the 1×4 boards used to tie the tops of the trusses together while the trusses are going up. 9 ft is chosen so that two courses of OSB panels can be installed below the 1×4 boards.

To read the rest of this tutorial, click here:

Here I’m showing the first two trusses installed. It should be noted that when we left the site the previous week, the safety pole had an OSB strip mounted along it as shown and we had no roof trusses on site. The Gray Ghosts came in during the week, found the trusses had been delivered and added OSB to the middle of the web area on the two end trusses. They also removed the OSB on the safety pole so that the match up would remain perfectly vertical. In addition they cut OSB panels to fit each end truss, numbered them and the matching truss and left the panels in the front hall for us to find. A real time saver by our friendly Ghosts.

The drawing shows the marking of the trusses on the house at 2 feet apart with the exception of the first one from the starting end. These are 3/4 inch short of 2 feet, e.g. 23 1/4 inches for the first end of cap to truss spacing. The rest are on 24 inch marks from that one. All the trusses are actually on 2 foot spacing. The initial measurement is from the end of the cap plate, but the center of the first truss is 3/4 inch to the right making it centered on the 2 foot mark. The marks are spaced so that the mark can line up with the edge of the truss rather than trying to align to a mark under the truss.

The 1×4 temporary brace boards were also marked on 2 foot marks so that the tops of the trusses could be aligned easily as they go up. The board is marked 3/4 inch in from the first edge, that edge is marked “start” and then the rest marked 24 inch centers from the 3/4 inch mark. This allows the start end to lap the first truss completely and the other marks to align with the centers of the trusses.

Shown in the illustration are special alignment tools made for Cobb Habitat. The first was made by a Gray Ghost from 2×4’s and some of these are still around. I think they still make them.

Aleignment braces being picked up from a wheelbarrow. Note some are a little more refined than others, but all work the same. Drop them over two truss rails and they will be held rigidly at the proper spacing, truss-to-truss.

My drawings are all made with some free software, called “Google Sketchup”. Takes a little getting used to, but I did all four drawings for this article in a couple of hours.

This drawing illustrates the use of the 1×4 braces, the alignment tool, and the placement of angle braces within the underside of the top rails of the roof trusses. With Google Sketchup, once you have made a component (such as the first truss member in the top illustration), you can manipulate it in space and duplicate it anywhere. 2x4s and OSB are drawn in 3D in a matter of seconds and can be rotated and slid into place like real wood. The angle braces started outside of this drawing in free space and then repositioned and rotated in various directions to get it placed in the framing. Everything stays to scale and in perspective as you rotate things around, even look underneath. The angle braces greatly strengthen the house.

Here are pictures of one of the end trusses and of the house with the safety pole stripped of its OSB as we found it Saturday morning. Work of the Gray Ghosts.

Here are the OSB cutouts for the end trusses and the barge rafters already cut by the Gray Ghosts. Thanks guys! OSB is laid on the end trusses along the centers of the web and marked for cutout. The cutouts and the web are both marked so the the OSB can be lifted up to the installed truss and nailed on later. Hoisting a truss with the OSB installed can be done but it is a real strain and adds to the danger. Cutting the OSB from measurements after the truss is up is also possible but a real pain.

The barge rafter is easily cut on the ground using the truss as a pattern. The ends match the truss but so you will know, for a 5/12 roof, the angles are 45 degrees for the top cut and 67 1/2 degrees for the bottom cut. All four were cut in advance by the Gray Ghosts. Otherwise experienced volunteers would have done all of this before the last end truss went up so that they would have a pattern. Barge rafters go on the sloped ends of the roof on the drip line . I’ll have other pictures when I illustrate their installation later in this article.

Here we are installing the fifth truss. Note that multiple alignment spacers are in use and so is the long 1×4 board used for temporary bracing. I’m illustrating the use of the made-on-site forked Y’s to lift and guide the truss onto the frame of the house. The fellow poking his head up is in real danger. He is ready to duck and all the volunteers are told to move the trusses in small increments as he helps them guide it through. He tries to stay visible to everyone on both sides of the wall and that helps them protect him as well.

There are people on the inside guiding the truss with their own poles. The safety beam (often called the “sissy beam”) which bridges across the living room (not in these pictures, partially in the picture below) helps hold the other end of the truss when it bridges that room and also keeps the top end of the “A” from tipping over and dropping down into the house. Jeff calls the people using the Y’s guys – “Wyse Guys”. “Com’on wyse guys pick your end up higher”. The truss tends to catch on the walls and have to be lifted and shoved at the same time to overcome that.

Here the bottom of the truss is held in its approximate final position and the top of the A frame is rotated up to join the others. Notice the extra spacing tools on the right ready to slip over the new truss to hold it at 2 feet from the last one. The sissy beam is the big beam in the bottom left of the picture. The top of the truss was lieing on this and without it could have fallen into the living area. This beam is removed soon after the trusses are up. When the bottoms are right (adjusted to the 14 inch mark on the truss and to the 2 foot mark on the cap beam) and the tops are secured with the braces, the bottoms at each end are nailed with 3 nails in each truss. Two 16d nails on one side and one on the other. More might weaken the truss. The trusses are not nailed to the interior walls. Hurricane straps will be added later.

The technique for the last truss is different. There is little to no space to slide it over and if it slid off, it would be a disaster to a number of people. First a number of step ladders are leaned against the house. The truss is brought around and set up vertically next to the ladders and then hoisted to rest on the tops of the ladders as people with Y’s and others in the rafters keep it from toppling over. Then the volunteers climb the ladders to the third step from the top and, on command from our fearless leader, lift it up as it is guided into place by those on ladders inside. The bottom edge is set against the deadwood and the frame shifted to the proper mark and the top secured with alignment tools. Then the hammers fly, driving nails into the side of the bottom chord into the deadwood on the wall. Job well done! The 14 inch markings on the trusses must have been good as they all lined up perfectly when sighted down the ends!

You can see from the picture above that some volunteers have already started the house-wrap. Actually it is almost done. They were working on this end as the other end was receiving trusses and on the other end as this end was being finished.

This picture was taken about a half hour earlier. One is unrolling and another smoothing. The wrap is nailed in place with roofing nails (don’t use the bottle cap nails!). The rolls are 9′ long. We cut a foot off the roll with a circular saw to get an 8 foot roll. Start 12 inches from one corner and nail it at the top corner at the top of the OSB. Roll it around that corner and nail it along the top edge as you go along. Cover all the windows and doors and X cut them out later. When the next corner is reached, stop and go back and nail the wrap approximately every 3 feet along the center and along the bottom. Keep rolling along the walls corner to corner. Use special tape for all seams.

This is one of the few houses where the wrap is right side up. The tendency is to wrap left to right and that always results in wrap that is upside down. Right to left as shown gets it right side up. It doesn’t matter, I’m just making noise here for the fun of it.

Cut windows out of the house wrap with a utility knife, by cutting diagonally from corner to corner and leave the triangle pieces to be folded and stapled inside. Repeat for the doors but cut out the bottom triangle and discard.

The bottom of window frames get a special treatment after the wrap is installed and stapled back. First the corners receive a window tape that wraps around the window opening and folds down across the bottom window plate. Then a second tape is run across the entire window that laps over as shown to the wall wrap. The cut corners of the tape are completely sealed in this manner. Water that gets between the wrap and the siding near the window has no place to accumulate and keeps on going down the outside.

Here is a wrapped window and door opening. The wrap is folded back and stapled before the window or door goes in. The top flap of the window also receives special treatment. The top flap is trimmed down to fit over the installed window flange and is not stapled inside. The idea is to have the wrap shed any moisture coming from above to the outside of the window flange and not carry it inside. The volunteers doing the wrapping don’t worry about this. They wrap and window installers take care of the top flap as they go along. The important part is not to cut out the entire window opening outline.

Here the top flap has already been trimmed and is being carefully tucked in on top of the outside of the flange above the window being installed. Thus water runs down the wrap and into a channel on the window that keeps it outside.

The window is secured to the wall with screws or nails in the slots. They can be purposely left a little loose so they can move as they expand and contract. The tapes, siding and interior trim will keep them from rattling or moving any noticeable amount inside. It doesn’t seem to matter much either way in this climate. I’m just reporting the recommendations.

The technique is to apply the window wrap foil across the bottom of the window, then the left and right edges and finally across the top of the window. That way all the water flows down like shingles on a house, shedding water all the way.

Here a volunteer is installing deadwood over the interior walls. These serve the purpose of providing a place to nail the drywall ceiling. In this case there are two 2×4 boards nailed to the interior wall cap plate, one on each side. You can just see the ends sticking out above the wall running left to right. The deadwood is needed only on the walls parallel to the rafters.

Meanwhile the decking is going on. Notice the house wrap however. The top flap is sitting above the window waiting for it to be properly placed and taped. Nothing left to chance. The plywood sheets are handed up by strong guys and gals on demand from the crew above. They position the first sheet on the 47 1/4 mark on the truss top rails and center the end on the 4th truss. That is 6 feet from the end (3 each 2′ openings) leaving a 2 foot overhang. That will be trimmed later to 12 inches or whatever the SPM desires.

OSB has a smooth side and a rough side. Always install with the rough side up. Snap a line from the 47 1/4 marks at each end of the roof and use that as a guide for the deck installation. I know we made marks on every truss as asked but the more experienced deck crews always chalk a good line, end to end.

Full 8 foot sheets are installed across the entire front and rear of the house before beginning a second course. The decking crew nails each sheet at the top and bottom of each sheet into the truss, 10 each 8d nails to the sheet. Others come back later and nail the sheets on a pattern of 6″ down the seams and 12″ in the fields. Someone on a ladder can do the bottom edge safely. I did that part.

The second course starts with an OSB sheet cut to be 4’x 4′ square and is offset to the second truss. This offsets this course for the second run and all the subsequent runs are similarly offset. The sheets overhang on each end by two feet.

When a rafter is bowed too much or kinked it is sometimes necessary to add “sister” 2x4s to add a little wood on one side or the other to catch the edges of the plywood properly. Here is a sister board going on for a slightly kinked rafter. Beams are sometimes repaired this way if a worrysome looking crack is found in the wood.

The OSB along the top ridge is left with a 1 1/2 inch gap on each side for installation of a ridge vent later. The gap does not extend all the way across. It should end on the 3d truss from each end. This is an inside view of the gap covered with tarpaper. The tarpaper is not cut out until the ridge vents are reay to install. The roof on the right side has not yet been covered so the H clip gap still shows.

This is an “H clip” (hurricane clip) that must be used between each course of the OSB. This is a view from the inside showing the clip causes a small intentional separation. The clip helps hold the boards together during high winds and big pressure differences from the attic to the outside.

H clip close up.

The decking is snapped with a chalk line at the proper overhang. This house was designed for a 12 inch overhang, but one side was offset to 10.5 inches and the other left at 12 inches. The reasoning seemed to be that one side would match the porch better at the 10.5 setting. Here the excess is trimmed off the 12 inch side with a skill saw moved up the roof in a continuous walk. I think he has done this a few times! A perfect cut. Watch out below! You can see the beginnings of lookouts already installed.

Lookouts are “U” shaped with the uprights extending from the wall to the barge rafter when it is installed. The portion shown is difficult to install (swing a hammer) if the barge rafter is put up first. Thinking ahead. More about them later.

This is the first barge rafter going up. This is the other end of the house from the previous picture and the far edge has not yet been trimmed. The rafter is patterned to the truss while it is on the ground. As mentioned earlier, it was cut by the Gray Ghosts during the week. The technique is to lift it up on one end and let the roof crew pull it up and position it. They have clamps ready. The rafter is lowered over the edge, pulled up to the OSB and carefully positioned, then clamped in place. This is the “long” one and fits at the top end to the OSB on the other side and aligns 3/4 inch above the bottom edge of the OSB at the bottom. The fascia along the bottom edge will lap this piece and make everything right. The “short barge rafter” fits against the bottom edge of the long one. Once clamped, they are nailed into place from the top on both sides of the roof using 8d nails. The barge rafters go on before the tar paper when possible.

Here is the same end of the house showing details of the installation. Notice the first (long) one is installed flush up against the overhanging roof on the other side and the second is butted against it. Notice that they are numbered and marked for each end of the house and where located.

This picture, taken earlier in the day, illustrates the installation of the panels pre-cut by the Gray Ghosts. Each panel had been laid out and cut to fit the truss while it was on the ground. Terry is crew-chiefing the installation on one end of the house and carefully fitting the panel into place.

Before the last end is closed up there are some things that must be done to ensure that nothing is left out of the attic. Terry is shoving long 2×4 boards to be used as catwalks and to stabilize the bottoms of the trusses which “float” above the interior walls. Installing these boards will stabilize the bottoms of the trusses so that they remain on 2′ centers for ease in drywall ceiling installation. Extra lumber also goes in for use by the heating and air guy to build an attic floor for his system. He will be happy to find sheets of OSB and lumber for his HVAC platform waiting for him. Sometimes the roof truss design includes a couple of trusses that have some of the web relocated to make a pocket for the HVAC unit.

Here one of the boards Terry shoved in earlier is being nailed down to the bottom rails of the trusses. Notice that she is using the spacers to maintain uniform and exact spacing, essential to those installing drywall ceilings later. Without these boards in place the rafters can move back and forth and could make ceiling installation a pain.

This photo illustrates two items of interest. The first is the drip edge applied to the lower edge of the roof. It typically goes on before the tar paper and the tar paper laps over it (bottom horizontal edges only). The second is the ladder hold-off positioned on blocks and secured by bent nails so that the ladder will not contact the drip edge or the roof as it is being installed.

Once the barge rafters are in place (or if rain threatens) the felt (tarpaper) can be applied. The felt is installed with the bottom edge even with the bottom edge of the roof. It should not overlap the roof edge. Overlap the higher courses by locating the bottom edge on a line on the felt, typically 4 inches. It must be installed as flat as possible. Larger wrinkles will show through the shingles. Nail tightly with plastic-cap roofing nails 3 across the felt and about 3 feet apart across the roof. Note: after doing this, we were told to go back and put more nails in the edges. We ended up with about 1 foot apart. We will install the shingles on our next work day.

Here the drip edge is applied over the tarpaper and against the new barge rafter. The drip edge has a wide and a narrow edge. I had a closeup picture of the drip edge ends, but somehow it got lost – sorry folks.

Install the wide edge on the roof and the narrow edge drops down over the fascia or barge rafter. Once again, the drip edge goes under the tar paper on the horizontal (bottom) edge of the house and on top of the tar paper along the sloping edge over the barge rafters. Attach the drip edge with 7/8 roofing nails every 24 inches. Overlap the joint where the downhill run meets the horizontal run at the corners. Overlap the drip edge at joints by 1/2 inch. This requires cutting away one of the webs with a metal shear.

This is a hurricane strap of the kind used to attach the top wall to the roof trusses. One end of each goes on the top wall cap and the other ends connect to a truss. This is in addition to the 3 nails already holding the truss in place at each end. The hurricane strap helps keep the roof on in high winds. Each strap is rated for holding down under more than 500 pounds of uplift and about 150 pounds of lateral load. Use 5 each 8d nails in each end of the strap. If a different style strap is furnished, a nail goes in every hole. Do not drill holes or use oversize or undersize nails. Different nails may be required for larger size straps. Use what you are told to use.

The first strap is properly installed. The second one had to be removed and replaced because the web extended down onto the cap plate and would interfere with the drywall on both the ceiling and the wall.

Now here is a Handy little device for where hammers are hard to swing. It is a palm hammer aka palm nailer. Pneumatically operated, it tap-tap-taps a nail in a matter of a couple of seconds. You insert the nail head into the working end, it grips it with a magnet and as soon as you touch the nail to the wood with a small amount of pressure, it drives it in. It will drive nails in very tight places and is easy to use.

I found this one on the Dewalt Factory Outlet web site for $89.00. It weighs 2.6 pounds, drives 6d to 16d nails. Stick a nail head into the opening at the bottom, press it to a board and it goes right in in about a second. Sears has a different brand for $215 made by Jet, claims 1000 blows per minute. I have no idea what the difference is between all these. Porter Cable has one about $119.00 to $130.00 They come with various attachements. Drives nails from 3d to 70d ???. Surely that is a typo. It did say it drives “stakes”. Home Depot did not list any.

Another safety feature is a the T shaped horizontal boards nailed across the end trusses at each end of the house. This consists of 3 2×4’s nailed with one of the 2×4’s trapped edgewise between the other two. This very strong structure was attached to the end trusses to reinforce them. It was made on site.

Here a caulk seal is being applied rather thickly to the outside walls to discourage wind, water and insects. The drywall that goes up later will cover this no matter how thick. Also the floor covering and base cove will catch anything that might show. Most of our caulk is donated. In the case of plumbing walls on the outside wall such as in the laundry, the caulk seal goes to the outter of the two walls. It is not needed on interior walls.

Here a window and door caulk is applied to the concrete in an exterior doorway just before the door is dropped in. A larger dollop is in the cut-nail hole. This is the first of several passes to make sure that it is well caulked. The door has already been checked for fit.

Here the door is being nailed in. The door was fitted, caulked, then carefully adjusted for vertical in all directions using the long level. This header and frame were a good fit. If the header is more than an inch above the door, then a 1×4 would be nailed in to the bottom of the header. Either side can be raised to make the gap at the top of the door even all the way across, meaning the gap you see above the swinging part of the door, not the frame vs door. The hinge side must be set vertical and then nailed with a single 16d galvanized finish nail through the brick mold on the outside top. This nail is left partially out so it can be removed if necessary. Check the door and then nail the center and bottom of the hinge-side brick mold. Then adjust the gap on each edge of the door making sure the the top and latch sides are even.